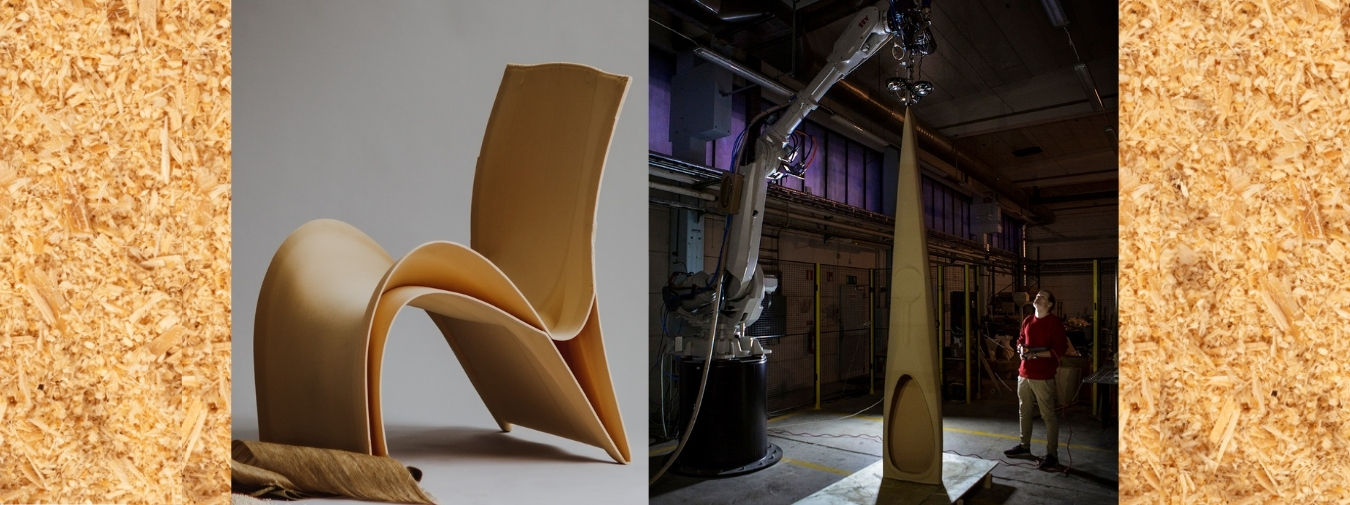

3D-Printed kayak in biocomposite

Pelle Stafshede decided to move away from traditional development methods and turn his attention to additive production using biocomposite instead.

Read more

Supporting innovation and identifying new ways to utilise by-products are two areas that Moelven is more than happy to contribute towards. The Wood Region is a project that makes this possible.

The Wood Region is part of the Bioinno project, which aims to promote entrepreneurship within the forestry bioeconomy in Värmland and Dalarna. The testing and development facilities in Sysselbäck are a key resource for Bioinno. Innovators can use the test environment to produce large-scale prototypes using biocomposite 3D-printers.

In the forest-dense area of northern Värmland, Moelven Notnäs Ransby AB’s sawmill can be found. Here, 150,000 m3 of trees are sawn each year. This creates both wood products and by-products, such as sawdust. Sawdust is a by-product that is currently burned for energy or sold to customers that produce chipboard.

When Peter Broberg, the CEO of Moelven Notnäs Ransby, was asked whether they wanted to help support a new innovation community where technology, renewable materials and creative people could meet, the answer was simple.

“If we can use by-products for things other than fuel, then that is a positive development that could generate added value for the raw material. Naturally, this is something we wanted to contribute to. Additionally, it is extremely positive for the local community that such an initiative is taking place in Sysselbäck,” Peter says.

Our goals are strongly linked to the UN's sustainability goals. This case is linked to climate-smart products and services and sustainability goal # 13: Stop climate change.

Read about Moelven's sustainability goalsThe Wood Region is a venue where new concepts can begin their journeys. Here, there is a machine park where 3D technology and wood-based biocomposite can be used to rapidly develop prototypes, which several companies have already used in their product development.

“The great thing about The Wood Region is that it is a community that is open to everyone, subject to certain conditions. The facilities and the staff contribute technology and expertise for the development of new sustainable products through additive production, or 3D-printing as it is also known. The material consists of wood and bio-based plastic, which is degradable and recyclable,” explains Annica Åman, Head of Communications at Paper Province, which part-funds The Wood Region.

“Nothing is impossible! Everything from sailboats to shoe heels and designer furniture is printed within the walls of The Wood Region. Here, for example, you can find the world’s largest 3D-printer for biocomposite, which makes it possible to print very large items. If the prototype is wrong, it can simply be run through a grinder and you can start over again using the same materials,” Annica explains.