One of the best in class at Moelven when it comes to waste sorting is Moelven Mjøsbruket AS. “The key is making it as easy as possible for employees,” says operations manager at Moelven Mjøsbruket, Petter Fjeld Bjerke.

Sorting options are available in the immediate vicinity of work stations. “Of course, plastic is sorted at the Packaging department and electrical waste is sorted by the electrician. And at the workshop we have a container for waste oil from the trucks,”explains Bjerke.

The sorting ratio of the entire Moelven Group is 83.7 per cent, with a target of 90 per cent. Mjøsbruket has been working to increase the degree of sorting for several years.

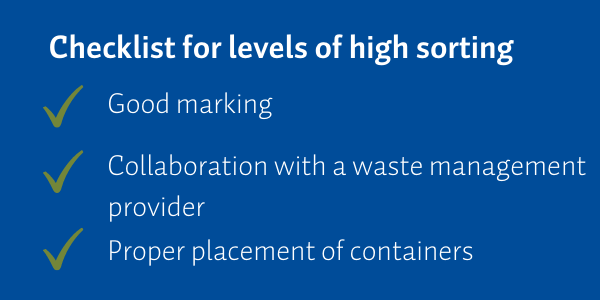

“Marking is also extremely important, so that we don’t spend time wondering where different waste goes,” Bjerke says.

Positive collaboration with waste management provider

Another success factor is the positive collaboration with Østlandet gjenvinning. They have conducted multiple site visits to establish which types of waste could be sorted differently.

I am impressed by the sorting ratio that Moelven Mjøsbruket AS has managed to achieve . I hope that more of our companies are able to benefit from the lessons learned from their efforts on clear marking, accessible placement and continuous improvements to the fractions that can be sorted.

“Previously, we used to sort plastic packaging and green plastic tape together. But the plastic tape has to be sent for energy incineration, whereas plastic packaging is now sent for recycling,” Bjerke explains.

The positive collaboration means that together they have managed to identify optimal sorting and the number of containers needed throughout the area to ensure easy use for employees.

The waste oil tank is located in the workshop, so it is easy to sort the waste correctly.

“We are lucky to have a sustainable material to work with, but it is important that we produce and sort waste in the most sustainable way possible. We must continue to work on identifying whether there is anything else that can be sorted into different fractions and ensure that all employees know what needs to be sorted where,” says Bjerke.

Moelven and the UN Sustainable Development Goals

To ensure that our work on sustainability has clear direction and a global perspective, we have chosen to connect our four main areas to the UN’s Sustainable Development Goals. The article you’re now reading is linked to “Safeguarding natural resources” and sustainability goal #13 Climate action.

Read more about what the different goals mean to us here